History of the Company

The origins of Traffic Construction Safety Devices began in the late 1987's with an idea to market and sell manufactured products made of recycled rubber and plastic. By 1989 our cofounder was working with major recyclers on the East and West Coasts.

By 1992 we had expanded our marketing to include several manufacturing companies in the United States, Canada, Mexico, and beyond. That year we also introduced recycled products produced in the USA. Working with our manufacturers we were able to offer a variety of recycled products and services. We soon diversified to include many other plastic and rubber manufacturing processes, and we began to market personal and highway-safety items, including parking blocks, speed bumps, wheel chocks, dock bumpers, snow poles, traffic control devices, and rubber flooring just to name a few - with our focus on the environment with most products 100% recycled.

By 1994 our manufacturers developed exciting new urethane processes in the development of traffic safety devices. Manufacturing processes became more effective and efficient through automation and decreased production time.

Our web presence began in 1996 with web pages featuring our products and services for internet users. This move helped us to expand to new markets and expand our customer service. Also this year we expanded our product line to offer new innovative technologies. Our global presence opened new markets for our products and service.

In 1998 new innovative products for traffic control became available after passing compliance testing in October of that year, giving our customers new opportunities and product options.

At the turn of the century we began to accept payments from credit cards to help facilitate speedy shipping. This bolsters our core commitment to excellent customer service throughout the United States and abroad.

In 2003 the rest of the manufacturing industry began to recognize the popularity of "green" and "100% recycled", and we continued developing, expanding, and servicing our customers with our environmentally friendly products - many new innovations.Our team grew in 2005 to continue providing superior service to our valued customers. More products and information continue to become available.

In 2010 our presence on the internet was increased with our current collection of websites. New detail and information is now easily accessible to our customers.

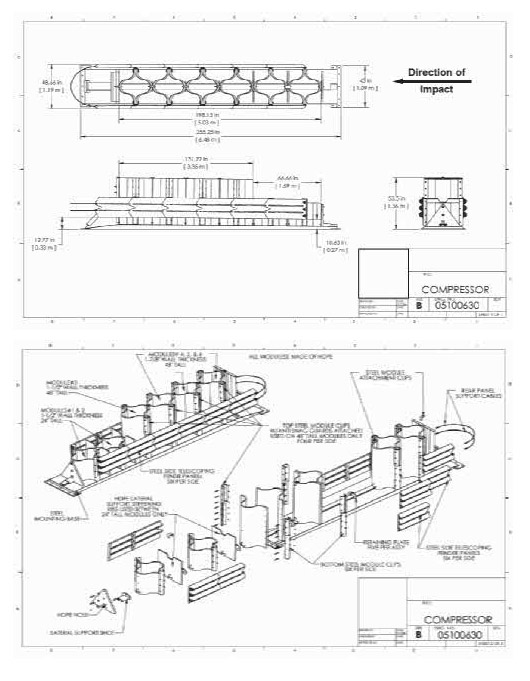

In 2011 we have introduced the New Enhanced Compressor Crash Attenuator that is NCHRP-350 test level 3. This new innovative crash device is a self recoverable attenuator designed to take repeated impacts without any additional recovery procedures and with minimal or no repairs.

More new products are being developed. Look for more quality products on our website and give us a call

- Passed all required NCHRP-350 TL-3 Tests - FHWA Approval Pending

- Compressor is a self recoverable attenuator designed to take repeated impacts without any additional recovery procedures and with minimal or no repairs

- Overall length 21' 3" - Attenuator Module/Effective length 16' 6"

- Delivered assembled and ready to install - eliminates on-site assembly

- Bright powder coated yellow solid steel Uni-BaseT requires only 10 bolts to secure the Compressor to the pavement

- Compressor's assembled design combined with the Uni-BaseT construction makes job site installation fast, easy and safe- one crew can safely install several units in one day

- Compressor's specially formulated attenuator modules are injection molded from HDPE plastic and are designed to more efficiently absorb energy in a shorter distance

- Attenuator modules are pre-flattened to provide more consistent results after repeated impacts

- Compressor's telescoping ultra high strength steel side panels re-direct side impacts with minimal damage to attenuator modules or panels

Download Compressor™ PDF below: