Dock Bumper & Bracketing Application Guidelines

Dock bumpers are designed to protect the loading dock, building and equipment from impact by docking trailers. Weighing in at well over 40,000 lbs., a fully loaded trailer can cause costly damage to the dock if the shock is not absorbed by properly applied bumpers. No two loading docks are the same. Use the following guide to determine which Dock Bumper best suits the specific needs of each one.

Questions to Ask:

- What is the dock height (from grade level to top of dock floor)?

- Is there an existing cantilever or other dock extension present? If so, what size is it?

- What is the percentage of grade (slope) of the dock approach (rise of approach in 50' - dock height / 600")

- What is the condition of the concrete where dock bumpers will be mounted? Will it accept new anchors?

- Can new bumpers be welded to the dock pit curb angle on one side?

- What is the percentage of air-ride trailers versus others using this dock?

- What different bed heights of trailers use this dock?

- What different widths of trailers use this dock?

Determining Bumper Projection :

Most conventional loading docks use a 4" projection dock bumper with great success. This keeps the trailer far enough away from the building wall so that traditional foam dock seals are not over-compressed and that dock equipment is protected.

However, when the dock approach is declined (i.e. trailer travels downhill when approaching the dock), it is critical to increase the bumper projection so the top of the trailer doesn't impact the building wall or over compress dock seals, which can also increase their pressure on building walls. The goal should be to keep the trailer a minimum of 4" away from the wall at all times.

Increasing bumper projection can be accomplished in several ways:

1. Creating a cantilever dock by adding concrete to the face of the dock.

2. Removing existing dock bumpers and installing an Extension Bracket to extend bumper.

3. Installing an Extra Projection Bumper of the appropriate projection. In many cases, choosing options 2 or 3 results in a quality, economical installation.

Note: Always consult OEM specifications of other loading dock equipment installed at dock position (dock levelers, truck restraints, dock shelters, etc.) for specific dock bumper protection requirements.

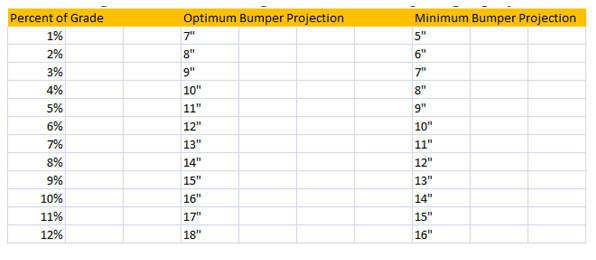

The following should be used as a guide for determining bumper projection:

Determining Bumper Size and Mounting Location:

Ensuring adequate protection here will limit the potential damaging effects of trucks missing the bumpers.

Bumper Width:

Identifying the width range where trailers will impact the dock will determine how far apart the bumpers are installed and whether a horizontal, vertical, L-Shaped or combination of these types will work best.

Bumper Height:

Once the lowest and highest impact points (off grade) of trailers (including any unforeseen challenges that might raise the trailer - packed snow, ice or debris) are understood, the appropriate bumper size that matches the height requirements can be chosen.

Note: Consider L-Shaped Bumpers to offer the best combination of horizontal and vertical protection.

Above Dock Requirement:

If the impact height is determined to be ABOVE the dock level there may be a need for Above Dock Riser Bracketing. Note: Trade-off may be necessary when considering Above Dock Riser Brackets as they may cause intrusion into the door opening.

Bumper Installation Considerations:

Dock bumpers must be solidly anchored to the dock face since they will be subjected to vigorous, repeated impacts. It is important to choose the best fastening method.

Concrete installation:

Minimum 5/8" diameter anchor embedded a minimum depth of 5" into solid concrete. If concrete is damaged consider using Bumper Mounting Plates.

Steel installation:

Welding to embedded plates on dock face, curb angles, etc. Note: Only Steel-Faced and Laminated bumpers have steel edges for welding. Molded bumpers must be anchored or mounted with a pre-studded weld plate.

Combination of Concrete and Steel installation:

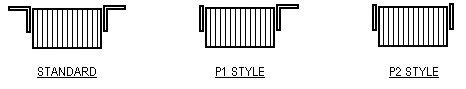

If solid concrete is available on one installation side and a good steel curb angle on the other, Steel-Faced and Laminated bumpers can be ordered with steel angles both sides (standard), angle one side flat on other (P1 option), or flat plate both sides (P2 option).

- Warehouse Safety-Doc Bumpers-Wheel Chocks-Knuffi

- Dock Bumper Guidelines

- Dock Bumper Bracketing

- Steel Laminated Dock Bumpers

- Laminated Rubber Dock Bumpers

- Molded Dock Bumpers

- Extruded Rubber D_Bumper

- Wheel Chocks for Tracks, Aviation

- Trailer Stands-Stabilizer Jacks

- Dock Lights

- Stop and Go Lights

- Sure Lites Traffic Lights

- Knuffi Soft Edge Bumper Guards

- Rack Protection

- Wheel Stops Parking Blocks

- Traffic Speed Bumps

- Plastic Speed Bumps